Systems protecting areas with the risk of deep-seated fires begin at 65 and dust collectors in HVAC systems are protected by 75 CO2 concentrations. The different types of suppression systems have different periodic inspection intervals and maintenance requirements.

Etool Evacuation Plans And Procedures Emergency Standards Fixed Extinguishing Systems Occupational Safety And Health Administration

One of the best features of a CO2 Carbon dioxide suppression.

. Testing and maintenance of CO2 fire suppression systems are necessary to ensure the system is functioning correctly. 1 System function test per NFPA 12. Fire suppression systems are typically required to be inspected and tested every 6-months or annually depending on the type of system.

According to NFPA 12 Carbon Dioxide Extinguishing Systems the minimum required CO2 concentration for fire extinguishment is. So if you have an existing CO2 system you have to go back and upgrade your system to meet these safety requirements including adding lock-out valves. When fire suppression inspection deficiencies are found our experts immediately forward you the information thats necessary to repair the system.

A Inspection and testing. Together all of these documents create Californias unique requirements for maintaining fire sprinkler systems. Maintenance testing and Inspection of Fire Protection System and Appliance Maintenance testing and inspections shall be carried out based on the guidelines developed by the Organization Refer to MSC1Circ1432 as amended including the amendments by MSC1Circ1516 and in a manner having due regard to ensuring the reliability of fire-fighting.

So on the discharge piping from the cylinders you need to have a valve in the line that you can close and then lock out and tag out when you go into that occupied space or normally unoccupied space if its total. Request a Fire Suppression Inspection Quote. National Fire Protection Association NFPA 12.

All portable fire extinguishers semi-portable fire-extinguishing systems fire-detection systems and fixed fire-extinguishing systems including ventilation machinery shutdowns and fixed fire-extinguishing system pressure-operated dampers on board the vessel must be inspected or tested at least once every 12 months as prescribed in. CO2 Carbon dioxide suppression systems raise the level of carbon dioxide that is concentrated in the fire which neutralizes the oxygen supporting the fire and thus extinguishes the flame. 848 Revised Guidelines for the approval of equivalent fixed gas fire-extinguishing systems as referred to in SOLAS 74 for machinery spaces and cargo pump-rooms as further amended by MSC1Circ.

It should include the date time and person doing the inspecting. CO2 suppression systems that protect areas with high voltage begin at concentration levels of 50 CO2. Maintaining fire sprinkler systems can be complicated.

Gene Ptacek and Son Fire Equipment has a staff of professional technicians that are certified licensed and manufacture trained to properly maintain your fire protection equipment so that when needed it will function as required. Specific requirements for halocarbon agents can be found in NFPA 2001 Standard on Clean Agent Fire Extinguishing Systems Inert gas An inert gas agent contains one or more of the following gases as components. Recording and documenting every step of the process must be done.

2007 California Fire Code CFC Chapter 9. When possible recommendations include details such as budget pricing and the duration of the repairs or required maintenance. The average CO2 fire suppression system protecting an enclosed room starts at 34 CO2 levels.

Our team of experts understand the importance of a properly functioning suppression system and. 2 Fire Alarm function testing - NFPA 72 Chapter 10. The system must successfully pass the fire tests in IMO MSCCirc.

Typically industrial suppression systems utilize banks of high pressure CO2 cylinders to release CO2 in a 100 concentration to displace the oxygen as quickly as possible. Inspections shall be scheduled a minimum of 48 hours in advance. Helium neon argon or nitrogen and that can also contain carbon dioxide as a minor component.

CO2 Carbon dioxide can be used on many types of fires and for many commercial and residential applications. CO2 Fixed Fire Extinguishing System Inspection Requirements Automatic Fire Suppression System Find Details about CO2 Fire Suppression CO2 Fire Suppression System from CO2 Fixed Fire Extinguishing System Inspection Requirements Automatic Fire Suppression System - Shenzhen Asenware Test and Control Technology Co Ltd. This article helps you make sense of the who when and howincluding licenses schedules and proceduresof fire sprinkler inspection testing and maintenance in California.

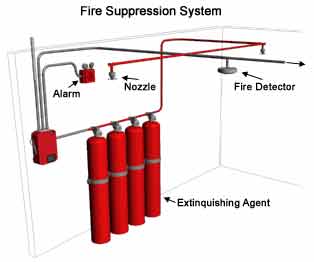

This includes inspecting the initiating devices release devices piping nozzles cylinders and signaling devices. NFPA 12 details the requirements for testing a CO2 suppression system including the points in the room timing requirements and the necessary concentration thresholds.

Introduction To Fire Suppression Systems

Inspection And Testing Requirements For Clean Agent Suppression

Ind Dry Chemical Fire System Kidde Fire Systems

Fire Protection For Dust Collectors Co2 System Spark Trap Arrestors

Fire Suppression Inspection Checklist

What Is A Co2 Fire Suppression System And How Does It Work

High Pressure Co2 Hp Co2 Fire System Kidde Fire Systems

Kidde Carbon Dioxide Fire Suppression System Co2 Suppression Systems

0 comments

Post a Comment